Where we started

Our company started back in 1975 when it used to be called WELDING CONTRACTOR.

The company was founded back in 1975 as Welding Contractor to serve the local market. Since its rebranding in 1998, Hi-Technolab Ltd has constantly been readapting its services to reply to expert local welding needs at best to existing and emerging industries.

Today, Hi-Technolab Ltd is proudly dedicated to meet the specific welding requirements of leaders of the Hotel, Food, Petroleum, Automobile, Marine and Sugar Industries.

Our company started back in 1975 when it used to be called WELDING CONTRACTOR.

5 years later, our company changed its name to SOUDURE SERVICE for the next 18 years.

Since 1998, we are known as Hi-TECHNOLAB Ltd.

Hi-Technolab strives to make the difference. Our fully-fledged and highly-trained team of 20 experienced and dedicated professional welders, riggers, fitters and turners all place customer service and satisfaction first on a daily basis.

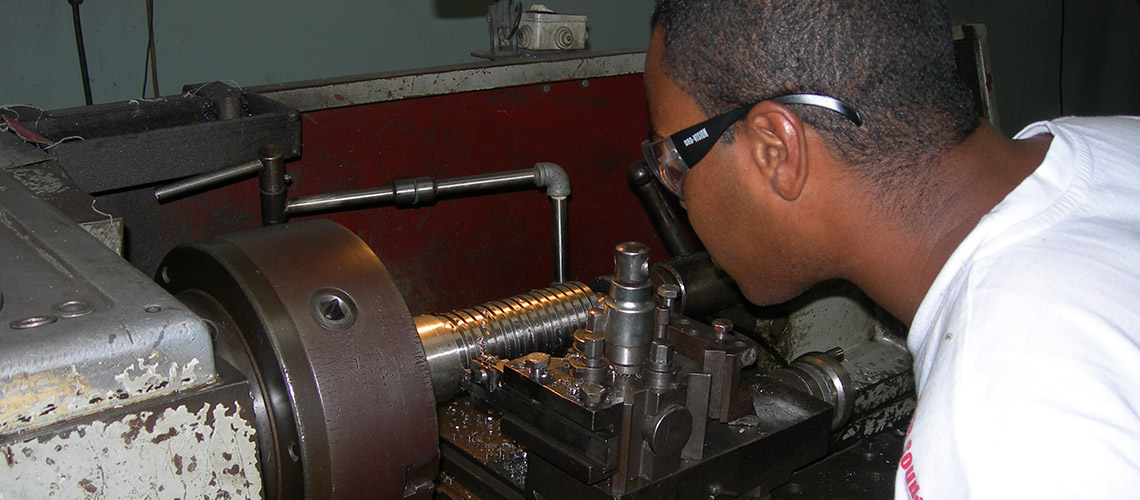

Our reboring machine facilities range among our value-added-services. By enabling us to repair your machinery on site, this services contributes to minimise your breakdown time and displacement costs. In case of emergency, High-Technolab remains your quickest solution.

Hi-Technolab welding services include steel, aluminium, stainless steel, cast-iron, bronze and copper etc. We offer MIG/MAG, TIG and ARC eutalloy & Rototech as well as fitting and turning facilities. Other competencies encompass various metal works, cold welding on piston shafts, cast iron cylinder heads and blocks, fabrication and repairs.

Our TIG, MIG, ARC, Rototech and Eutalloy weld technicians receive ongoing training and continuous updates on new tooling and technology.Hi-Technolab welding works include the following:

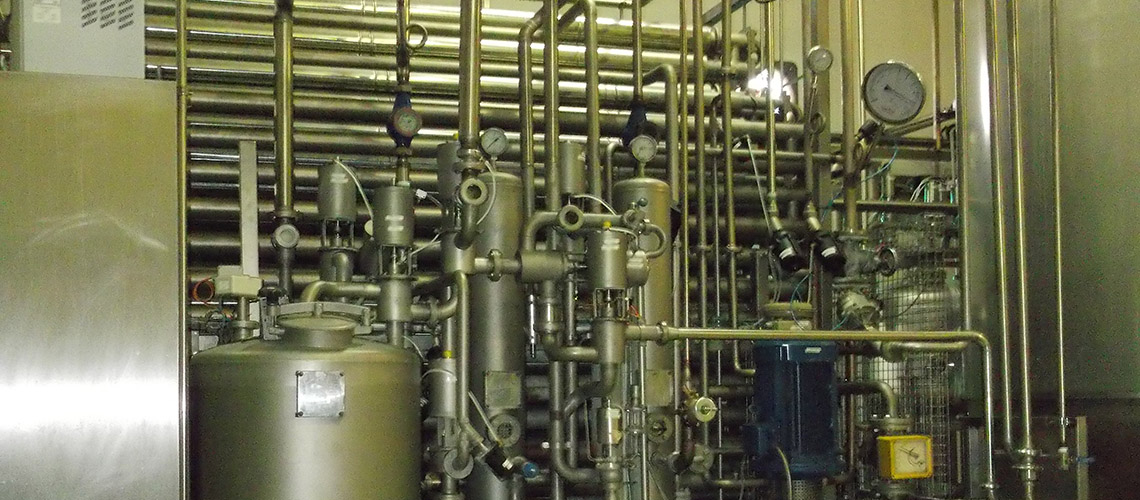

Thanks to its reliable team of professional coded welders, Hi-Technolab today partners with leaders of the local Food and Petroleum industries for their ranges of specialised welding works.

We assist them in strict conformity with applicable hygiene and industrial standards.

Our workshop is fully equipped to reply to current petty and major welding, fitting and turning repair needs mainly for the Marine, Sugar and Automobile industries.

We can provide 24/7 repair and maintenance services

Hi-Technolab is equipped to provide quick and reliable expert on-the-spot welding and fitting services to players of the Sugar and Marine industries. Thanks to our reboring machine facilities, we are able to repair our customers’ machines on site within restricted time frames. For emergencies, you can therefore rely on Hi-Technolab. (We can offer a 7/7 24/24 service).

Living on an island equals to maximising shipping transport including pleasure crafts and facilities. Today ship repairs have no secrets for our team of expert welders who have reliable know-how when it comes to repair: propellers, gearboxes, drive shafts, engine blocks and cylinder heads (aluminium, cast-iron, bronze and stainless-steel).

In case of breakdown, Hi-Technolab caters for emergencies by proposing on-site reboring machine facilities. Our technicians can reach your operational site within a restricted time frame and cater for your urgent outdoor fitting and turning needs on the spot. Such interventions lead to minimise your breakdown times and reduce your machine displacement needs.

Our workshop is fully equipped to repair aluminium alloy wheels, oil sumps and cylinder heads on a quick basis. This service is a real bonus for owners of cars and other vehicles which need to be fixed rapidly and within budget.

More than 40 years Experience